Experience,

Quality, and Value.

In-house fabrication capabilities give Blackeagle customers ultimate quality control while maximizing construction project timelines for greater efficiency. Plus, we fabricate superior metal products constructed to ASME U, R, NB stamps and 45 Welding Procedure Specifications (WPS). We preserve pipe integrity, accommodate thermal expansion and contraction, and increase elevation to allow for insulation clearance. We’re also the leader in fabrication of launchers and receivers for the oil and gas industry across the U.S. Also, our shop can produce pressure vessels up to 80 feet in length, 100,000 pounds, and 11 feet in diameter.

Blackeagle is the leading provider of fabricated products for the oil and gas industry in the western U.S.

Experience

Blackeagle has fabricated superior metal products for three decades, with the technical and project management experience to get every job done right, on time, and on budget.

Quality

ASME U, R, NB stamps and 45 Welding Procedure Specifications (WPS) qualifications, signifying expertise and the ability to deliver quality products.

Value

Highly experienced and trained personnel, time-proven processes, and a state-of-the-art facility provide efficiency and unbeatable value. Expert advice, on-time delivery, and a quality product – all at competitive pricing!

Blackeagle Fabrication at a glance:

Engineering & Design

Fabrication

Prep & Paint

QA/QC

Inventory Control & Transport

Pressure Vessels

Blackeagle fabricates the finest-quality pressure vessels in the industry. Up to 80’ in length, 100,000 pounds, 11’ diameter. Choose us for our ASME code shop, design, fabrication, surface prep, and paint all in one facility, Section IX Qualified weld procedures up to 8” thickness, and the highest-standard quality control program in the industry.

Vessel types include: separators, coalescing filters, slug catchers, surge tanks, heater treaters, gas treatment, knock out vessels, and contactor towers.

Launchers and Receivers

Blackeagle is the leader in fabrication of launchers and receivers for the oil and gas industry across the U.S. We’ve been doing it for more than 29 years. Customers trust our unmatched capacity and experience, quality, and customer service. High-volume fabrication means competitive pricing. In-house painting promotes efficiency that reduces delivery schedules. As an ASME code shop, our qualified welding procedures meet the highest of industry standards. Every product receives the highest-quality, detailed shop drawings. Project managers oversee the fabrication process and just-in-time delivery for customers across the country.

Pipe Clamps and Shoes

With no need to weld supports directly to pipe, using Blackeagle hardware for your next construction project helps to preserve pipe integrity. Accommodate thermal expansion and contraction, increase elevation, and allow for insulation clearance. Customers prefer Blackeagle clamps and shoes for their industry-leading design, uncompromising quality, fast delivery times, an unbeatable pricing.

Pipe clamps are available in sizes from 1” to 36”. Available options include wedge blocks, isolation pads, and painted, galvanized or mill finish.

Pipe shoes sizes range from 1” to 10”. Elevations allow for insulation, with temperature ranges from -20 F to 400 F. Available in painted, galvanized or mill finish.

Well Site Piping

Although well site piping has been traditionally fabricated on-site, you can save money, reduce schedules, and provide a higher-quality product by having Blackeagle build it ahead of time in our ASME code shop. Many of the industry’s leading E&P companies have already switched to shop fabrication to lower costs, increase quality, and provide uniformity.

With no rig pay or per diems, you will reduce costs over field fabrication by up to 40%. Compressed schedules mean faster time to product sale and increased revenue, too. Shop fabrication to your specifications means all well site piping meets your standards. As an ASME code shop, Blackeagle provides the highest of industry standards. Building ahead of time means no waiting on field crews or weather. Take days off your schedule with pre-built well site piping installed with just a few field welds.

Why choose Blackeagle’s ASME Code shop over field fabrication?

Items traditionally fabricated on-site can be more efficiently designed, fabricated, tested, and painted in Blackeagle’s shop and shipped directly to your project location.

REDUCE COSTS—UP TO 40% REDUCTIONS OVER FIELD FABRICATION

- Process efficiencies and lower labor costs

- No rig pay or per diems

GUARANTEED QUALITY – STANDARDIZED PROCESSES OF AN ASME CODE FACILITY

- Inspections and testing performed on every item on site

- Uniform products – built and tested to your exact specifications

REDUCE SAFETY AND ENVIRONMENTAL RISKS ON YOUR SITE

- No more permit hassles or problems with waste disposal

- Limit your safety exposure by fabricating in our facility

WHEN-YOU-NEED-IT SCHEDULING; NO MORE DELAYS

- Build ahead of time – take days off your schedule

- Product inventoried and delivered when needed – no waiting on field crews or weather

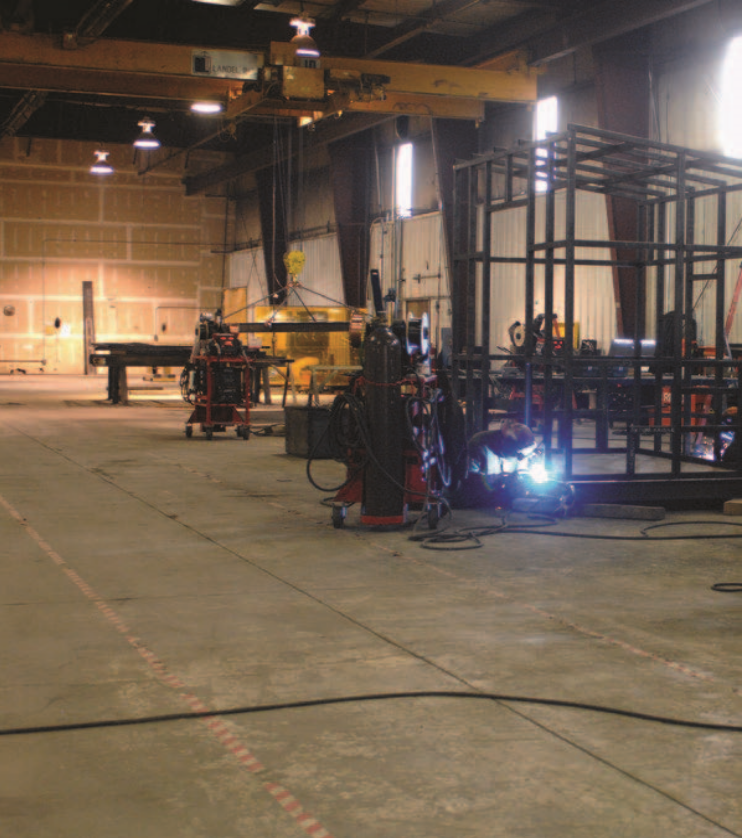

OUR 85,000 SQ. FT. FABRICATION FACILITY

- Built-for-purpose fabrication facility

- 11 overhead cranes, 12 acres of yard, 100,000 lb. rail system

For more information, please contact: fabrication@blackeagleenergyservices.com